News & Updates

News & Updates

Blog

|

3min

With all there is to learn at this year’s Propulsion, it will be impossible to leave without a long list of actions and strategies to improve your business in 2024.

March 20, 2024

By

Anna Troiano

|

Editor in Chief, Converged

News & Updates

Blog

|

2min

Whether you want to accelerate growth, unlock new opportunities for your business, or feed inspiration for innovation, Propulsion 2024 is where you need to be.

February 21, 2024

By

Anna Troiano

|

Editor in Chief, Converged

News & Updates

Blog

|

3min

Coming together as a company is about more than just aligning on business goals, it’s about building the bonds required to meet them. Part of our blog series “The CEO Lens.”

February 16, 2024

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

3min

The next time your flight gets delayed, consider how your experience can be applied to your customer success management. Part of our blog series “The CEO Lens.”

December 20, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

3min

Coming together as a company is about more than just aligning on business goals, it’s about building the bonds required to meet them. Part of our blog series “The CEO Lens.”

February 16, 2024

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

3min

The next time your flight gets delayed, consider how your experience can be applied to your customer success management. Part of our blog series “The CEO Lens.”

December 20, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

2min

Learning a customer is unhappy is always scary. But, according to Propel CEO Ross Meyercord, it could also be a golden opportunity to deepen the relationship.

November 3, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

2min

Overcoming the dread of performance evaluations is easier said than done. Here are some tips from Propel CEO Ross Meyercord.

September 29, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

3min

The three levels of trust that make or break SaaS relationships, according to Propel CEO Ross Meyercord. Part of our blog series “The CEO Lens.”

August 18, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

3min

From personalized product demos to speakeasy cocktails, there are so many opportunities to get some face time with Propel Software at Dreamforce 2023.

August 11, 2023

By

Anna Troiano

|

Editor in Chief, Converged

.png)

News & Updates

Blog

|

6min

Propulsion 2023 included real success stories for enduring revenue growth and strategies for uninterrupted product innovation in any market.

June 6, 2023

By

Dario Ambrosini

|

CMO, Propel

News & Updates

Video

|

31min

Political and economic analyst Bruce Mehlman provides an overview of macroeconomic trends across technology, geopolitics, culture, and climate.

May 17, 2023

By

Propel

|

Propel Software Solutions

News & Updates

Blog

|

3min

Returning May 17 & 18, here’s what to expect at this year’s biggest event for product innovators.

May 3, 2023

By

Propel

|

Propel Software Solutions

News & Updates

Blog

|

6min

How Propel's Ross Meyercord draws on his experience as CIO of Salesforce to inform success in his role as CEO.

April 28, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

6min

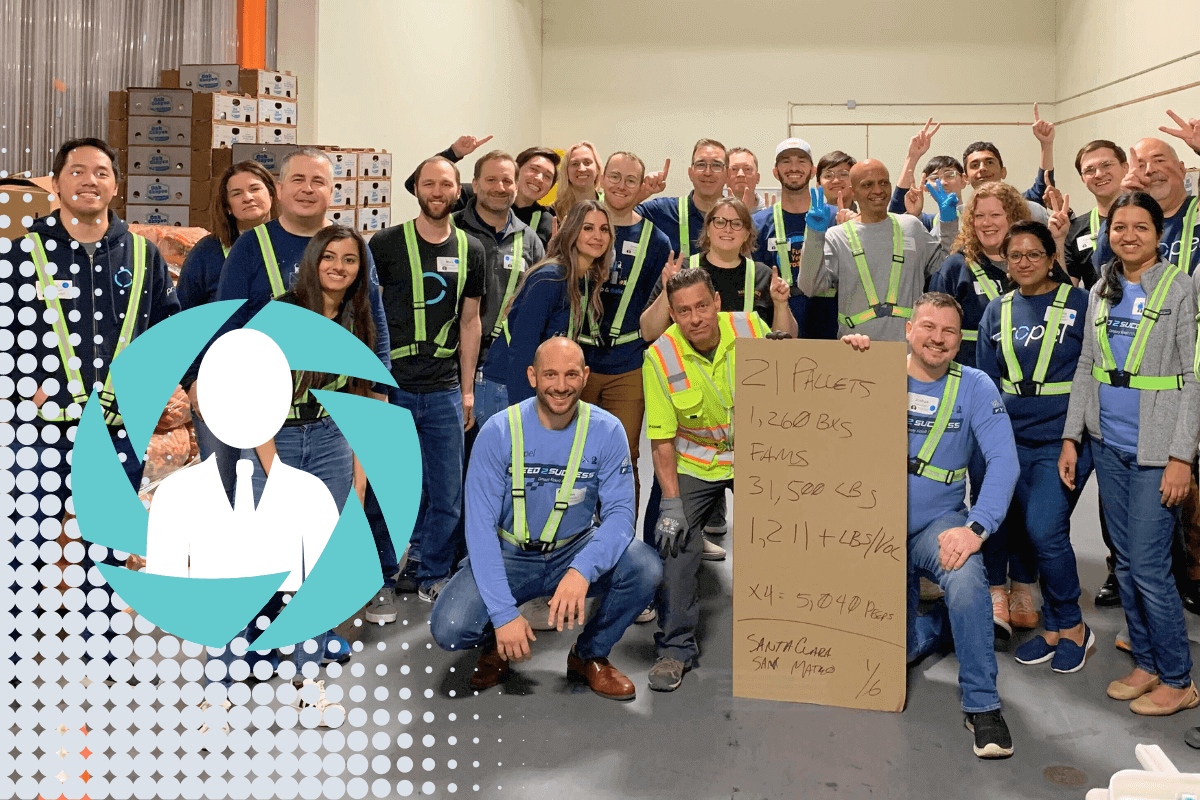

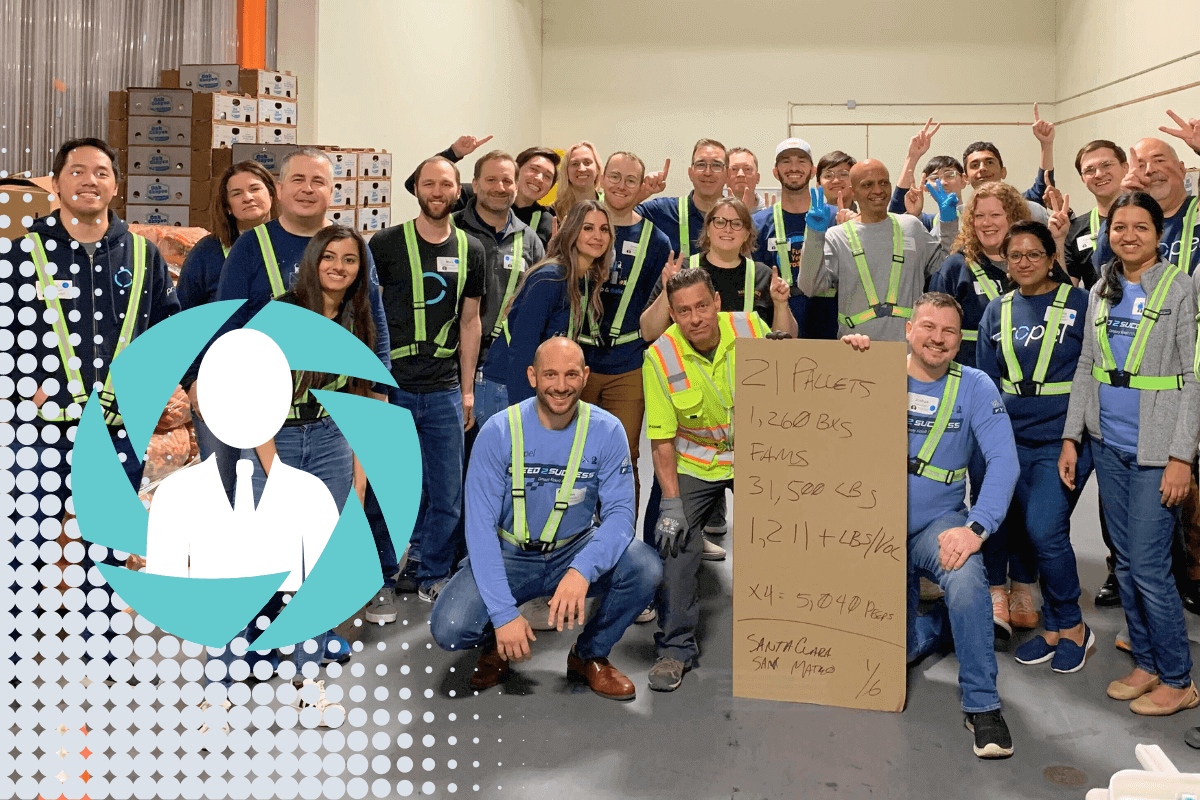

Coming from all over the world, almost all members of the Propel team convened to kick off FY24, the majority meeting each other in person for the very first time.

March 3, 2023

By

Ray Hein

|

Founder & Board Member, Propel

News & Updates

Blog

|

6min

In a recent survey conducted by Propel, a majority of business leaders in product and commercial teams indicate a need for product value management (PVM). Here are the findings.

February 22, 2023

By

Tom Shoemaker

|

VP of Product Marketing, Propel

%20Combats%20Disruption.png)

News & Updates

Blog

|

2min

An excerpt of CIMdata’s recent report entitled “Product Value Management in the Age of Disruption.”

January 6, 2023

By

Anna Troiano

|

Editor in Chief, Converged

News & Updates

Video

|

30min

Why is it important to be an agent of change for your business? At the first-ever Salesforce Manufacturing Summit in December 2022, Ray Hein of Propel and Michael Farr of MSA Safety present.

January 4, 2023

By

Ray Hein

|

Founder & Board Member, Propel

News & Updates

Blog

|

3min

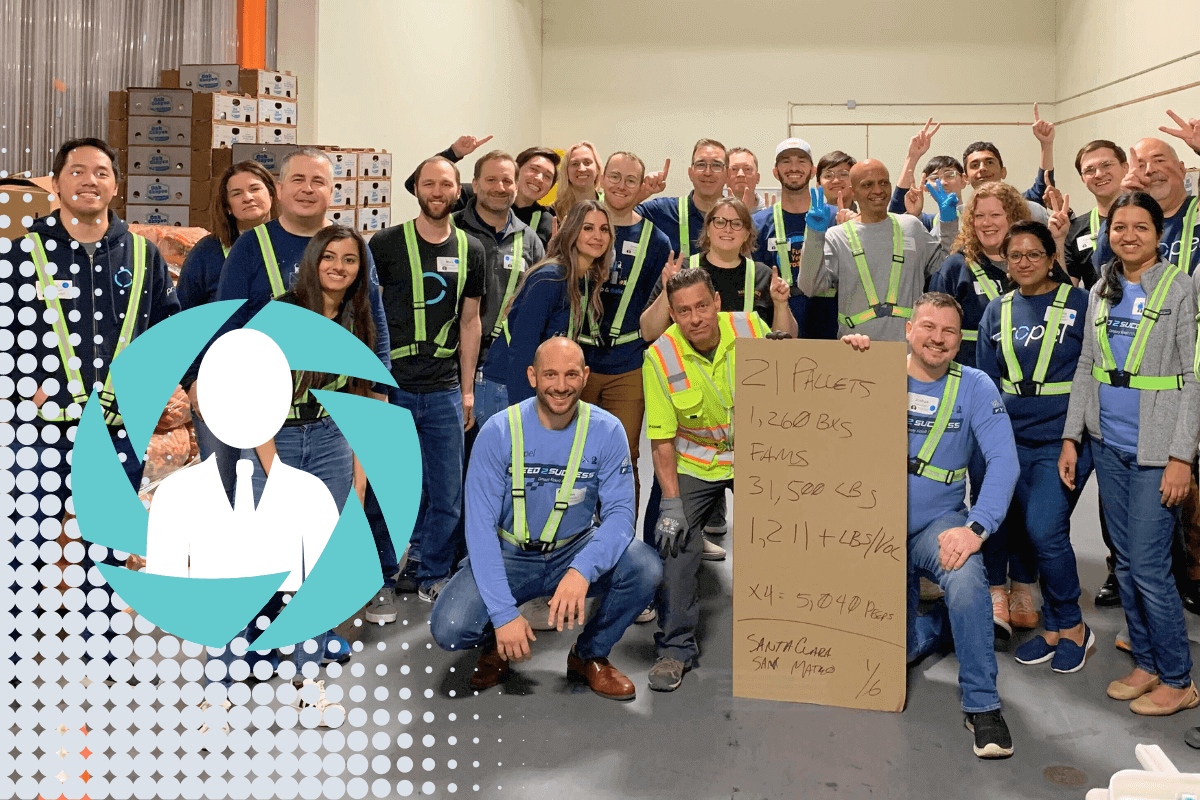

Cultivating the value of giving back in your workplace instills the message that even with the smallest of efforts, you can always make a big impact.

December 21, 2022

By

Ray Hein

|

Founder & Board Member, Propel

News & Updates

Blog

|

3min

Propel’s chief strategy officer Ray Hein on his learnings from a unique event for the manufacturing industry cloud space.

December 15, 2022

By

Ray Hein

|

Founder & Board Member, Propel

News & Updates

Blog

|

3min

A message from Propel’s new CEO, Ross Meyercord.

November 30, 2022

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

5min

With the Winter ‘23 release, the Propel platform will be based primarily on the Lightning Web Components (LWC) technology, allowing for more flexibility, customization, and automation.

September 16, 2022

By

Kishore Subramanian

|

CTO, Propel

News & Updates

Video

|

6min

Providing strategic value at every stage of the implementation process is the key to achieving mutual success. Propel's VP of Customer Success Mary De Frenchi elaborates in this Converged Conversation.

September 15, 2022

By

Mary De Frenchi

|

VP of Customer Success, Propel

News & Updates

Blog

|

2min

Celebrating 20 years, Dreamforce is back in-person this year—and Propel wouldn’t miss it. This time, we’ll be there as category leaders with game-changing new product capabilities to showcase.

August 29, 2022

By

Be'Anka Ashaolu

|

Former VP of Marketing, Propel

News & Updates

Blog

|

6min

Advice from two panels of manufacturing, high-tech, and medtech industry veterans sharing their insights about business transformation.

August 17, 2022

By

Anna Troiano

|

Editor in Chief, Converged

News & Updates

Blog

|

3min

Welcome to Converged, a new resource to educate today’s product companies and help them achieve success. Converged is a community of the best industry minds exploring topics and sparking conversations that matter to this moment.

August 8, 2022

By

Be'Anka Ashaolu

|

Former VP of Marketing, Propel

News & Updates

Blog

|

10min

From day 1, Customer Delight has been one of Propel’s key core values. Now, as the market becomes increasingly customer driven, our long-standing customer experience processes set us apart.

June 23, 2022

By

Mary De Frenchi

|

VP of Customer Success, Propel

News & Updates

Podcast

|

22min

Episode 10. Rule 10: Leading in the Customer-First Revolution

June 16, 2022

By

The Platform Rules Podcast

|

Tune In Biweekly

News & Updates

Podcast

|

40min

Episode 9. Rule 9: Get Set for Success. Customer Success Managers aren’t just helping install a new tool; they’re your partners, your counselors, and your success coaches throughout every stage of the implementation life cycle.

June 9, 2022

By

The Platform Rules Podcast

|

Tune In Biweekly

News & Updates

Blog

|

9min

Our third annual event was packed with inspiring heavy hitters from product companies and the industry cloud space, including tips, trends, and real success stories.

June 1, 2022

By

Dario Ambrosini

|

CMO, Propel

News & Updates

Video

|

30min

Vala Afshar, Chief Digital Evangelist at Salesforce, has interviewed hundreds of successful companies and noticed a pattern in how they operate. Here's what he learned.

May 24, 2022

By

Propel

|

Propel Software Solutions

News & Updates

Video

|

30min

Desktop Metal's growth during the pandemic is staggering. Co-founder and CTO Jonah Myerberg explains how they did it.

May 24, 2022

By

Propel

|

Propel Software Solutions

News & Updates

Blog

|

4min

Since the very beginning, Propel's five core values have shaped our culture. Now, they're setting us up for the next chapter.

May 12, 2022

By

Ray Hein

|

Founder & Board Member, Propel

News & Updates

Podcast

|

9min

Episode 1: Meet Your Hosts Chuck Serrin and Rachel Jang

August 23, 2021

By

Product Success Podcast: Quality and Medical Devices

|

Series One

News & Updates

Blog

|

17min

A successful supply chain internship can bring your business heightened operations through a new perspective and high-value potential from a low-risk opportunity.

June 17, 2021

By

Be'Anka Ashaolu

|

Former VP of Marketing, Propel

News & Updates

Blog

|

10min

Review this list of various job titles and descriptions within the supply chain so that your team can rise above the confusion and have a clear idea of specific roles and how to meet their requirements.

November 13, 2020

By

Dario Ambrosini

|

CMO, Propel

View All

News & Updates

Blog

|

2min

In 2015, the Propel founders took an innovative leap to build a cloud-based PLM on the Salesforce platform. Today, CEO Ross Meyercord reflects on the company's growth and the strategic foresight that has positioned Propel as a leader in its field.

April 24, 2024

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

3min

In Propel's Winter '24 release, we introduced a capability to connect item revisions of products directly to customer assets—here’s how it delivers substantial value.

April 10, 2024

By

Tom Shoemaker

|

VP of Product Marketing, Propel

News & Updates

Blog

|

3min

With all there is to learn at this year’s Propulsion, it will be impossible to leave without a long list of actions and strategies to improve your business in 2024.

March 20, 2024

By

Anna Troiano

|

Editor in Chief, Converged

News & Updates

Blog

|

2min

Whether you want to accelerate growth, unlock new opportunities for your business, or feed inspiration for innovation, Propulsion 2024 is where you need to be.

February 21, 2024

By

Anna Troiano

|

Editor in Chief, Converged

News & Updates

Blog

|

3min

Coming together as a company is about more than just aligning on business goals, it’s about building the bonds required to meet them. Part of our blog series “The CEO Lens.”

February 16, 2024

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

3min

The next time your flight gets delayed, consider how your experience can be applied to your customer success management. Part of our blog series “The CEO Lens.”

December 20, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

2min

Learning a customer is unhappy is always scary. But, according to Propel CEO Ross Meyercord, it could also be a golden opportunity to deepen the relationship.

November 3, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

2min

Overcoming the dread of performance evaluations is easier said than done. Here are some tips from Propel CEO Ross Meyercord.

September 29, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

3min

The three levels of trust that make or break SaaS relationships, according to Propel CEO Ross Meyercord. Part of our blog series “The CEO Lens.”

August 18, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

3min

From personalized product demos to speakeasy cocktails, there are so many opportunities to get some face time with Propel Software at Dreamforce 2023.

August 11, 2023

By

Anna Troiano

|

Editor in Chief, Converged

.png)

News & Updates

Blog

|

6min

Propulsion 2023 included real success stories for enduring revenue growth and strategies for uninterrupted product innovation in any market.

June 6, 2023

By

Dario Ambrosini

|

CMO, Propel

News & Updates

Blog

|

3min

Returning May 17 & 18, here’s what to expect at this year’s biggest event for product innovators.

May 3, 2023

By

Propel

|

Propel Software Solutions

News & Updates

Blog

|

6min

How Propel's Ross Meyercord draws on his experience as CIO of Salesforce to inform success in his role as CEO.

April 28, 2023

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

6min

Coming from all over the world, almost all members of the Propel team convened to kick off FY24, the majority meeting each other in person for the very first time.

March 3, 2023

By

Ray Hein

|

Founder & Board Member, Propel

News & Updates

Blog

|

6min

In a recent survey conducted by Propel, a majority of business leaders in product and commercial teams indicate a need for product value management (PVM). Here are the findings.

February 22, 2023

By

Tom Shoemaker

|

VP of Product Marketing, Propel

%20Combats%20Disruption.png)

News & Updates

Blog

|

2min

An excerpt of CIMdata’s recent report entitled “Product Value Management in the Age of Disruption.”

January 6, 2023

By

Anna Troiano

|

Editor in Chief, Converged

News & Updates

Blog

|

3min

Cultivating the value of giving back in your workplace instills the message that even with the smallest of efforts, you can always make a big impact.

December 21, 2022

By

Ray Hein

|

Founder & Board Member, Propel

News & Updates

Blog

|

3min

Propel’s chief strategy officer Ray Hein on his learnings from a unique event for the manufacturing industry cloud space.

December 15, 2022

By

Ray Hein

|

Founder & Board Member, Propel

News & Updates

Blog

|

3min

A message from Propel’s new CEO, Ross Meyercord.

November 30, 2022

By

Ross Meyercord

|

CEO, Propel

News & Updates

Blog

|

5min

With the Winter ‘23 release, the Propel platform will be based primarily on the Lightning Web Components (LWC) technology, allowing for more flexibility, customization, and automation.

September 16, 2022

By

Kishore Subramanian

|

CTO, Propel

News & Updates

Blog

|

2min

Celebrating 20 years, Dreamforce is back in-person this year—and Propel wouldn’t miss it. This time, we’ll be there as category leaders with game-changing new product capabilities to showcase.

August 29, 2022

By

Be'Anka Ashaolu

|

Former VP of Marketing, Propel

News & Updates

Blog

|

6min

Advice from two panels of manufacturing, high-tech, and medtech industry veterans sharing their insights about business transformation.

August 17, 2022

By

Anna Troiano

|

Editor in Chief, Converged

News & Updates

Blog

|

3min

Welcome to Converged, a new resource to educate today’s product companies and help them achieve success. Converged is a community of the best industry minds exploring topics and sparking conversations that matter to this moment.

August 8, 2022

By

Be'Anka Ashaolu

|

Former VP of Marketing, Propel

News & Updates

Blog

|

10min

From day 1, Customer Delight has been one of Propel’s key core values. Now, as the market becomes increasingly customer driven, our long-standing customer experience processes set us apart.

June 23, 2022

By

Mary De Frenchi

|

VP of Customer Success, Propel

News & Updates

Blog

|

9min

Our third annual event was packed with inspiring heavy hitters from product companies and the industry cloud space, including tips, trends, and real success stories.

June 1, 2022

By

Dario Ambrosini

|

CMO, Propel

News & Updates

Blog

|

4min

Since the very beginning, Propel's five core values have shaped our culture. Now, they're setting us up for the next chapter.

May 12, 2022

By

Ray Hein

|

Founder & Board Member, Propel

News & Updates

Blog

|

17min

A successful supply chain internship can bring your business heightened operations through a new perspective and high-value potential from a low-risk opportunity.

June 17, 2021

By

Be'Anka Ashaolu

|

Former VP of Marketing, Propel

News & Updates

Blog

|

10min

Review this list of various job titles and descriptions within the supply chain so that your team can rise above the confusion and have a clear idea of specific roles and how to meet their requirements.

November 13, 2020

By

Dario Ambrosini

|

CMO, Propel

View All

News & Updates

Video

|

31min

Political and economic analyst Bruce Mehlman provides an overview of macroeconomic trends across technology, geopolitics, culture, and climate.

May 17, 2023

By

Propel

|

Propel Software Solutions

News & Updates

Video

|

30min

Why is it important to be an agent of change for your business? At the first-ever Salesforce Manufacturing Summit in December 2022, Ray Hein of Propel and Michael Farr of MSA Safety present.

January 4, 2023

By

Ray Hein

|

Founder & Board Member, Propel

News & Updates

Video

|

6min

Providing strategic value at every stage of the implementation process is the key to achieving mutual success. Propel's VP of Customer Success Mary De Frenchi elaborates in this Converged Conversation.

September 15, 2022

By

Mary De Frenchi

|

VP of Customer Success, Propel

News & Updates

Video

|

30min

Vala Afshar, Chief Digital Evangelist at Salesforce, has interviewed hundreds of successful companies and noticed a pattern in how they operate. Here's what he learned.

May 24, 2022

By

Propel

|

Propel Software Solutions

News & Updates

Video

|

30min

Desktop Metal's growth during the pandemic is staggering. Co-founder and CTO Jonah Myerberg explains how they did it.

May 24, 2022

By

Propel

|

Propel Software Solutions

View All

News & Updates

Podcast

|

22min

Episode 10. Rule 10: Leading in the Customer-First Revolution

June 16, 2022

By

The Platform Rules Podcast

|

Tune In Biweekly

News & Updates

Podcast

|

40min

Episode 9. Rule 9: Get Set for Success. Customer Success Managers aren’t just helping install a new tool; they’re your partners, your counselors, and your success coaches throughout every stage of the implementation life cycle.

June 9, 2022

By

The Platform Rules Podcast

|

Tune In Biweekly

News & Updates

Podcast

|

9min

Episode 1: Meet Your Hosts Chuck Serrin and Rachel Jang

August 23, 2021

By

Product Success Podcast: Quality and Medical Devices

|

Series One

No items found.

View All

%20is%20Transforming%20Product%20Experiences.png)